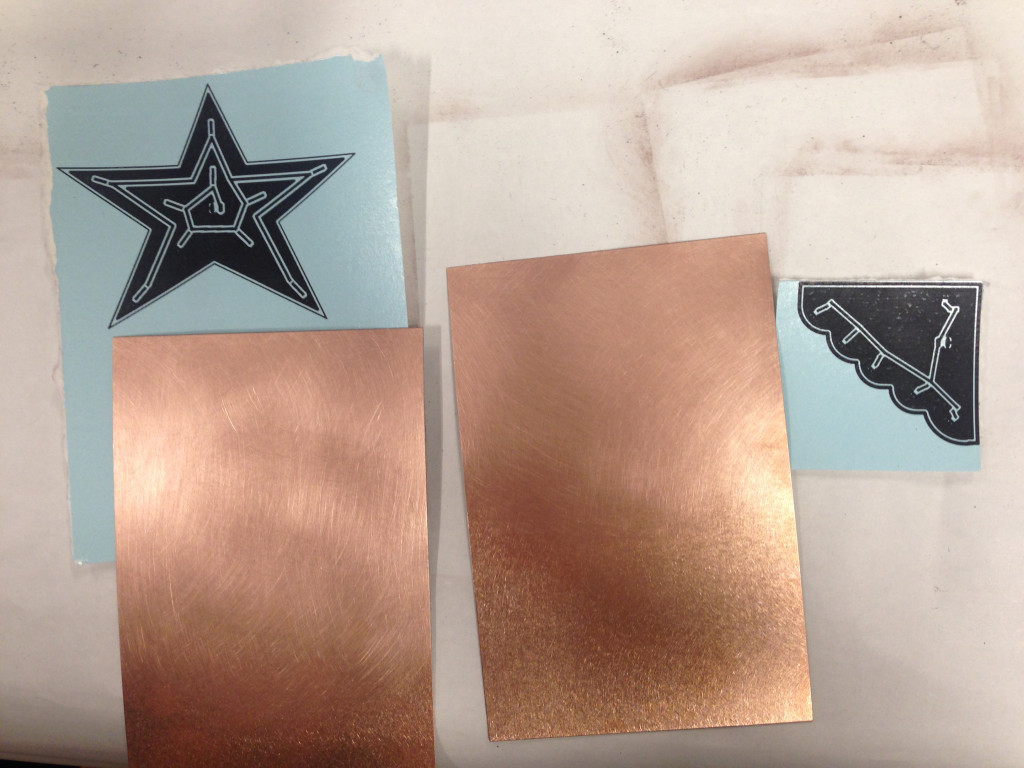

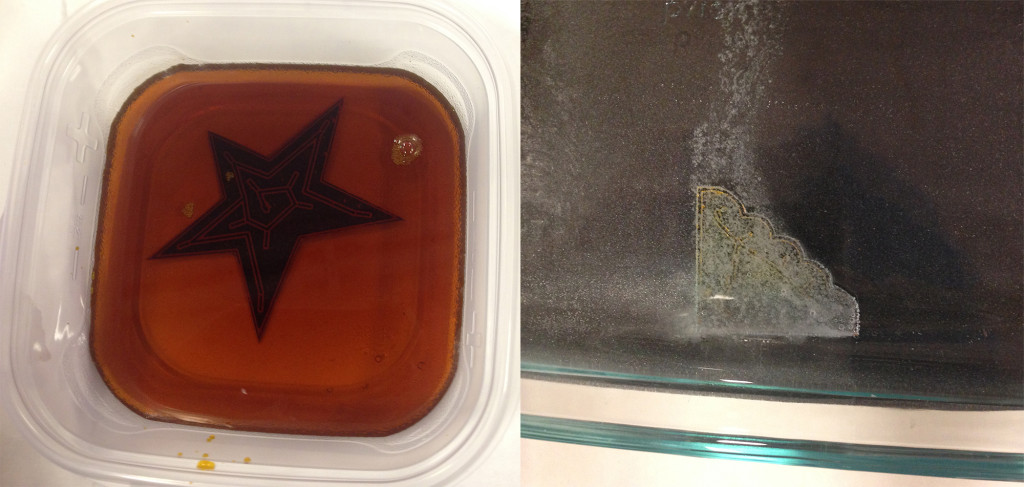

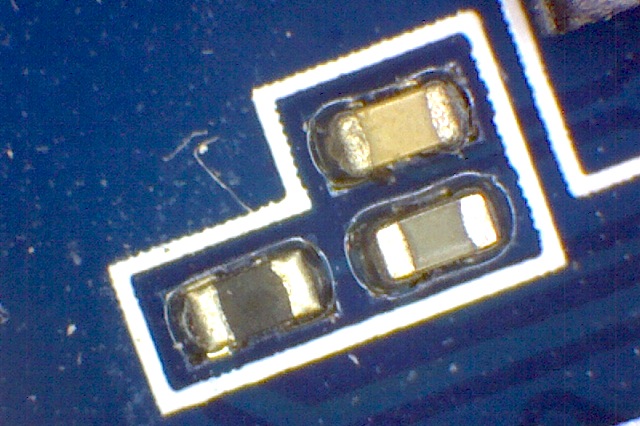

Last week we etched circuit boards in Circuit Design class. We had the choice of etching with acid or vinegar. My partner, Danara, chose acid while I tried with vinegar. Here’s what happened. The star design is Danara’s.

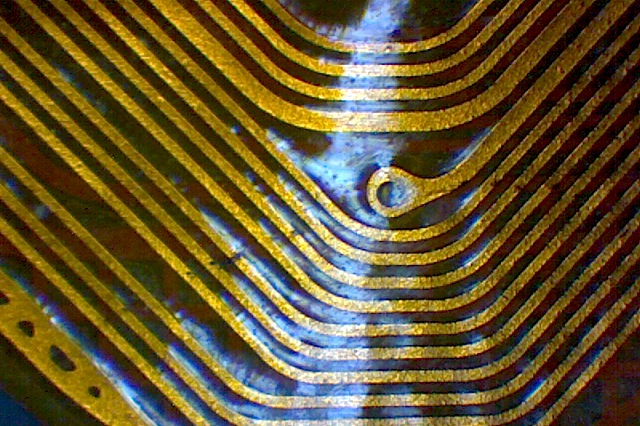

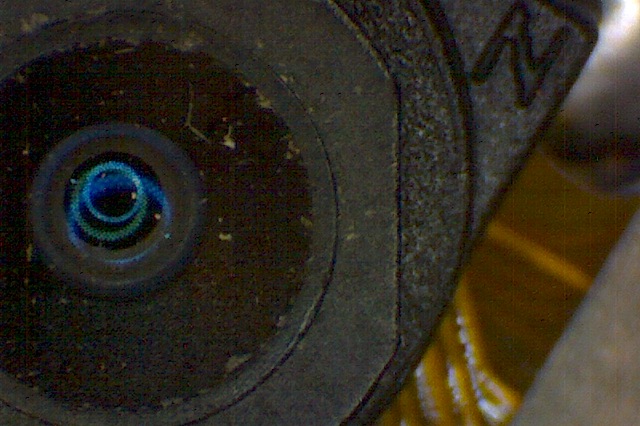

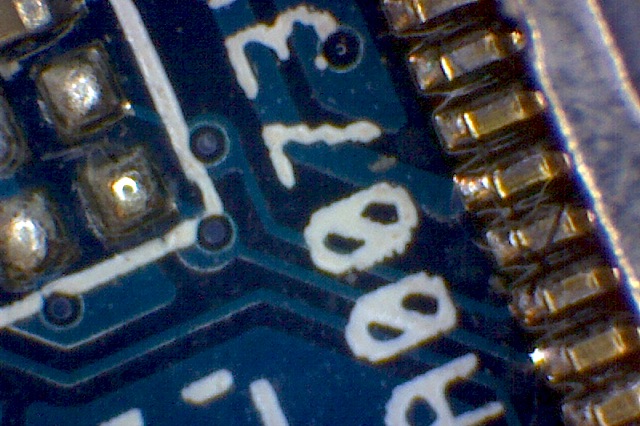

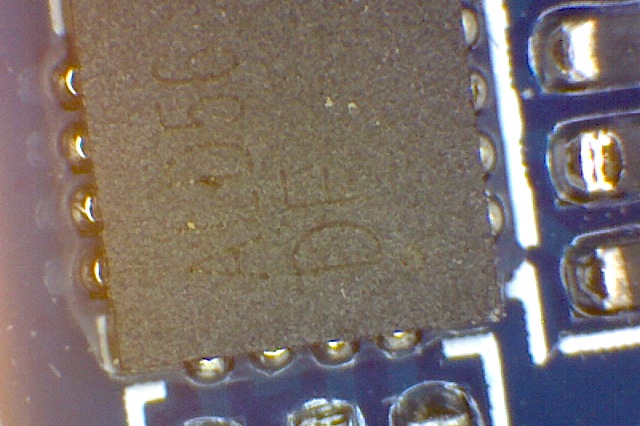

Danara’s board looked great, especially after it was tinted. Mine didn’t come out so well. womp womp

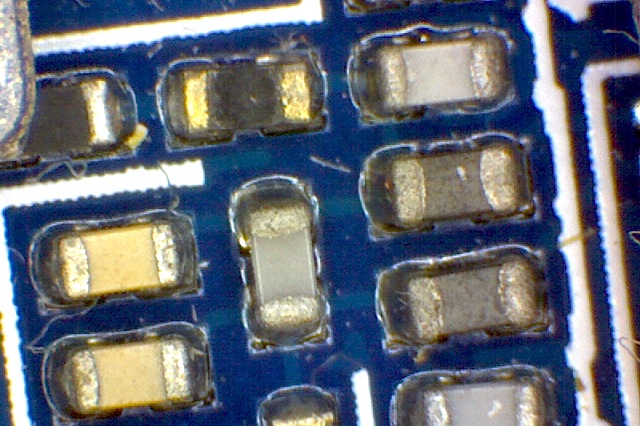

Vinegar took a lot longer. Because we had a couple of boards using the same container of vinegar, the residue from one board would float onto another board. Danara had her own container of acid, which did a super clean job. I may try again with vinegar, one day. For now, I’ll do over with acid.